start by removing the light fixture above the dinning table/lower berth

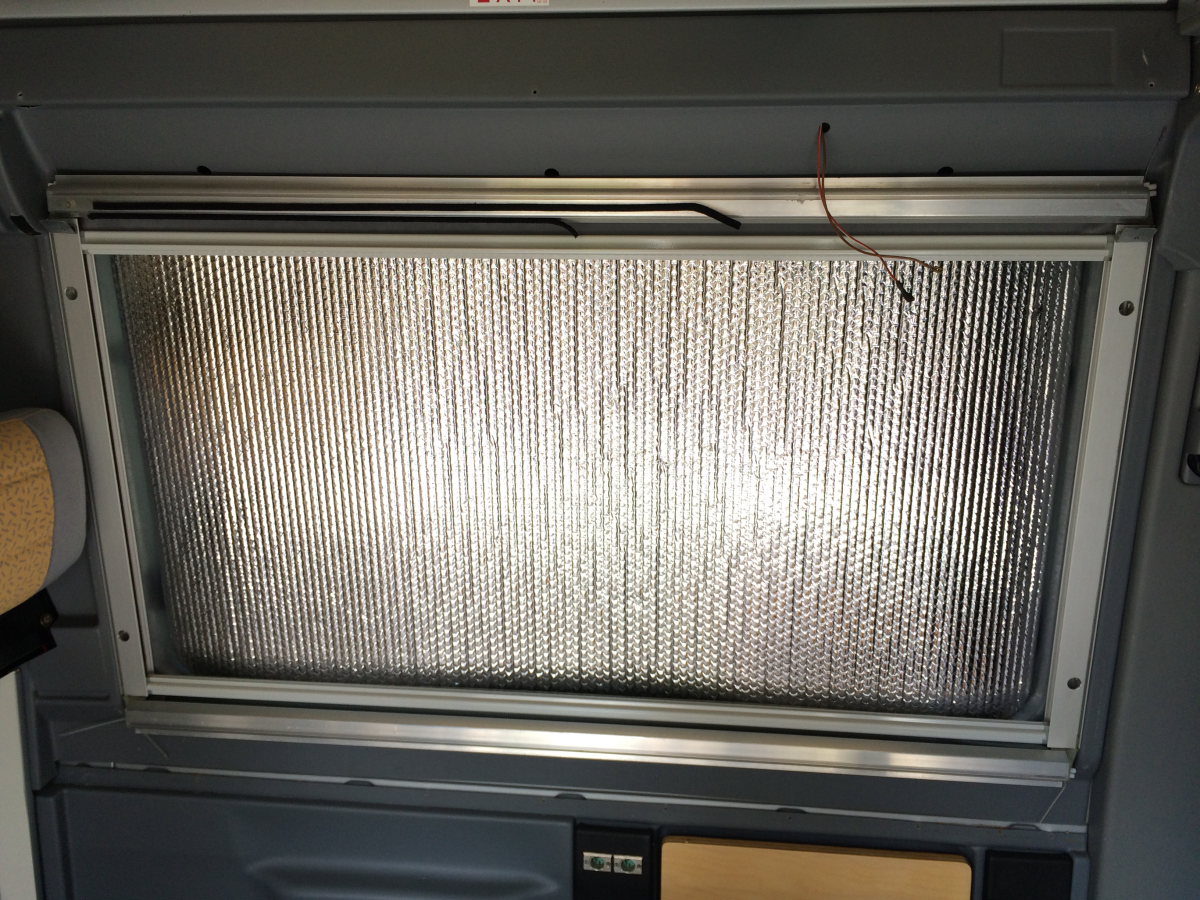

In case you wonder, the silver foil is my home made solar curtain to reduce solar gain. It is removable.

remove the dinning table support rail

these are the long screws

remove the screws on the upper horizontal trim

next step is to remove the two vertical plastic trim molding on the frame

they are very well made and pop off nicely by pulling on the side as in the photo

this is what the back of the vertical trim molding looks with the locking rail

same with the right hand side one by pulling out on the side

now the entire roller blind/screen assembly can be seen - held to the vehicle chassis with 4 screws

here you can see the screw through the access hole

length of the screws

exercise care not to rack the assembly

there are rubber grommets acting as spacers behind where the screws are and two additional ones at the bottom of the frame

6 spacers

all the fasteners and screw trim caps

finally i have a chance to undo the bad crease made by the previous owner

bad creases on both ends of the blind

if you look carefully you can see the magic behind the blind/screen - plastic pulleys for the steel cables that keep the blind and screen square through out their travel

this is my rough schematic of the steel cable and pulley system

After checking the rollers and blind and screen I could see what cause the laziness of the screen. I decided there is no need to tear down the roller to clean and lubricate the shafts. I just spray where the steel shafts meet the plastic support with silicone spray lubricant. I re-installed the roller blind/screen assembly. To my surprise the insect screen still will not retract.

Examined carefully I then see that the plastic window sill is rubbing against the rolled up screen. It is clear what happened. The plastic took on a different shape over time and have bowed out and came into contact the middle span of the insect screen roller.

here you can see the big gap formed between the plastic sill and the window frame

I knew what I need to do is to find a way to pull the sill towards the vehicle's steel frame. I feel with my hand and found the metal frame that I could add a screw to pull the plastic sill tight against it. That fixed it good.

one sheet metal screw and fix the problem for good

an awl really help to find the screw holes though the layers material

Mission accomplished. I fixed the insect screen, lubricated the rollers, and removed the unsightly creases that have irked me a long time.

Another good job of documenting the procedure!

ReplyDelete