The weak part of the compressor is the integral overload and pressure cutoff switch. Many years ago the breaker switch stuck on the ON position, but the pressure cutoff function was not affected. I had lived with it by just pulling the plug off the wall outlet to shut it off when not in used.

A few week ago I used the compressor again to pump up Isolde's tires. I heard the loud rush of high pressure air released from a distance. The pressure cutoff function of the switch finally failed. Fortunately there is the last defense that is the mechanical over-pressure release valve that open to prevent the dangerous build up of excessive pressure in the tank as the compressor pump is now ran away.

the easy part is to get the part number off the switch and start to find a replacement; it is cw208102av

The google search result is not encouraging. One hit is a list by the store that I bought the compressor from. The replacement switch is long out of production, and one will need to scrap the entire regulator, gauge set, and switch assembly and replace them with this kit.

drain out the condensate in the tank

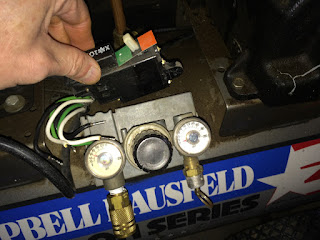

what make this switch unique is it is designed to work with the cast manifold assembly that has a direct air port the switch mates up to. There are two air ports on the switch. One is to detect the tank pressure that is directly mate to the manifold. The other, I would learnt later is a "unloading" valve to release the pressure built up in the piston cylinders so the compressor may be restarted without placing excessive startup load on the AC motor.

this is where the unloading air line connects to - via a compression fitting like the one used in John Guests's pottable water fittings; I had always thought John Guest invented the fitting but apparently not

the port where the switch mates up to sense the tank internal pressure

the plastic nipple that mates to the manifold with an o-ring

Doing a bit more reading and examining the possibility of using a cheaper switch without forgoing the existing gauges and regulator, and the manifold. I found this very generic pressure switch which you can buy from thiefBay or Amazon for more the less the same price. It is an educated gamble if I can make it work in the confined space of the compressor. I really don't want to spend more than I absolutely have to. $20 is my goal to get this repaired.

I figure I can rotate the valve/gauge assembly to adapt the cheap pressure switch while keeping the everything else

No comments:

Post a Comment