The Carver furnace and the new batteries sit side by side, and they are competing for the same space above the battery on the passenger side. The plywood shelf that elevates the Carver used to be secured to the Vanagon's plywood enclosure for the engine heat radiator and blower is now orphaned without a secure support. I have to figure out how to secure the side close to the battery before the furnace can be re-installed.

the exit and return air hoses compete with the battery; the air hoses were preexisting before this project

here you can see how confine this space constraint is - the battery terminals do encroach into the space where the hoses are but there is just enough space to route the hoses slightly higher

when I removed the old propane refrigerator I deferred the removal and capping of the propane line to it as it is not an easy project; today it got done

the line that need to be removed and capped is the one behind; there is not enough space to fit a wrench nor able to turn it; the two outer fittings must first be removed

even with the other copper tubing connections loosen there is still not enough space to work on the fitting; the entire regulator must be loosen from the high pressure port at the shutoff valve

the port in question is capped; and yes, Isolde has two propane tanks

all the wrenches involved

this Marshall model 260 is special that it is only 4 inches long; Marshall Brass Company ceased to exist long ago; this regulator is good and I put everything back together

i looked for something to cap the hole left from removal of the defunct gas line; a green wire nut does the job nicely

I manage to devise a way to secure the plywood shelf for the Carver furnace - secure it to one of the mounting T-nut for the heater/blower. This requires fabricating a bracket with a piece of angle aluminum.

One reason Germany produces excellent mechanical engineers is they have an apprentice program for hand on training. I heard that mechanical engineers to be all have to go though metal working training, like hand cutting a piece of metal and hand-filing it to high precision dimensions.

i cut this off squarely with a hacksaw

this is the bracket that will secure the orphaned plywood shelf to the floor by the battery using the existing T-nut (no new holes)

the Carver furnace is partially re-installed; I left the hoses free for now until I design a battery hold-down system - which also compete the space with the furnace air hoses

the interior beginning to look shipshape again - almost

By the way, I cannot be happier with the Alpine head unit driving all the MB Quart speakers. There is no lack of power with no hint of distortion (which tend to be clipping of the amplifiers because they run out of power supply headroom) playing very loud. If you sit on the bench seat you can feel the low bass from the woofers too.

the instrument console is back together and the trim for the Alpine head unit installed; only the microphone for hand free calling have yet to be installed - I want a chance of selecting the best location for it and that will require making some test calls

I have deliberated for the best location for the V/A digital meter. While it would be ideal to mount it at a location that is easy to read at normal eye level, I am unwilling to cut a new hole for it. I reason that I would not need to constantly check the parameters so mounting it at the opening of the heater/blower is the best choice for the sake of preserving the integrity of the Westfalia interior. Who knows, in time the meter may fail or replaced by something better.

I am all too aware not to commit to something unless I am sure I will never regret. One example is the holes that I had to cut to install the Carver furnace.

the black steel trim bracket for the old heater/blower will be retained and a piece of aluminum will be fabricated to house the V/A meter - no new holes

mother of nature is on my side - the weather outlook for the next 4 days are godsend with cool and dry days

Update 2015.10.11 14:03 PST:

Taking advantage of another cool day I got busy finishing up the installation of the new deep cycle batteries. I left the design and fabrication of the battery hold down until the very last because the batteries compete for the space above them with the comfort air ducting of the Carver furnace. My design and selection of using two group 24 deep cycle batteries cannot be more optimized. Group 27 would have been too large and anything else would not fit, or not maximizing the amp-hour of the new battery bank.

more testing of my hand sawing skill - I did well

the two notches to be cut

I use my Bosch jig saw for this work

a lot of hand filing to get to the right width

still too wide to fit between the two inspection caps

after a bit of trial and error and design as I went it is done

i chamfer the edges to clear the radii of the battery plastic housing

next is to find the hole locations for the two thread rods - I use a metal square to locate the holes to be drilled

here you can see how tight the space is - that is the reason the angle aluminum at this end has a gentle slope to give maximum space for the air duct of the furnace

the battery on the passenger side dictates the locations for both because it butts up against a bump on the body sheet metal

i cut 2 pieces of 1/4" thread rod for the battery hold down and drilled through the plywood flooring and the sheet metal floorpan

finally it is all done - the batteries are securely restrained and the Carver furnace is re-installed; i am extremely please with how well this turned out - Westfalia designers would be proud of my work

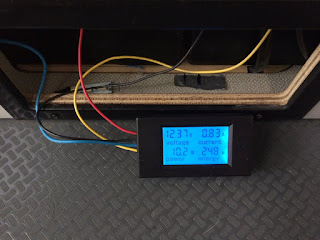

when set to low power, the Carver furnace draws only 830mA with the burner running; just 10.2W of power consumption

What remains now is to fabricate two aluminum panels, one for the V/A power meter and the other for refrigerator external power switch and the USB power ports for mobile devices by the main table stowed area.

No comments:

Post a Comment