Isolde's electrical system update are now down to the few items on the punch list to warp up the current project.

Why no solar power. you ask? I have entertained a small solar power system. There are however a lot of complexity due to (many self-imposed) constraints. I have decided it would be a future project.

I begun to fabricate an utility power panel taking advantage of the air vent for the old propane refrigerator. As planned it would house the main on/off switch for the new DC refrigerator, a USB power port for mobile devices, and a 12Vdc receptacle for used with a notebook computer.

the air vent opening - it is bisected by the table when stowed

the original propane (also AC and DC which essentially had their respective heating elements) generates a lot of heat; compared to the new DC fridge it looks as antiquated as a Soviet WWII tank

the DC refrigerator produces much less heat; in my refrigerator installation, I arranged for natural convection to help remove the heat by allowing air to enter on the storage space below the refrigerator and exits out through the vent holes along the top of the kitchenette

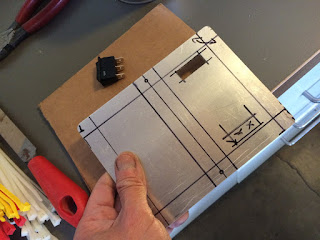

i cut a piece of 14 gauge aluminum that i have on hand with the same outer dimensions as the original vent grill; BTW, there is a few smart thinking in the original grill if you pay attention; these are the things that make Westfalia has no peers

i marked out the exclusion zones

i marked the cutout for the 11mm x 30mm rocker switch; i made a mistake forgetting this is the back side of the panel - i want the rocker switch closer to the outside so it is not obscured by the USB plugs during use

For hobbist electronic parts that requier a rectangular panel cutout is usually to be avoid at all cost. It is much easier to create a circular cutout than a square or rectangular one. However, there are situations that a rectangular switch is preferred for functional or aethestic reasons as in this case.

it is all manual work starting with small holes

the trick is to try to fit in the biggest holes possible to minimize the amount of hand filing

i use this cutter to cut off the aluminum between the holes - followed with hand sawing with a metal blade

the opening is now large enough to fit a file

you don't want to go crazy with the filing so check the dimensions often as you make progress

test fit with a 11mm x 30mm switch

Once the rectangle cutout dimensions are reached, i cleaned out all the burrs and followed with final sanding to give a matte appearance. I drilled the two mounting holes and de-burred them too.

i cannot cut the holes for the USB ports until it arrives and i tested it for acceptability; i have not decided on the choice of 12Vdc receptacle

i etch the surface of the aluminum hoping for a more dull surface but it made little difference

this rocker switch came from Brunnhilde's auxiliary water tank project which was replaced by one that is SPDT-center-off; i think the panel would look much batter if painted the same darker grey as the cabinet edge trims

With only the rocker switch the panel looks out of place and barren right now. It would look nicer once the neighbor moves in.

the switch has an indicator to signify when the refrigerator is switched on or off

still waiting for this USB power port to arrive via slow boat from China

next i set out to tackle the twin tank propane plumbing - i made an innocent mistake long ago of joining the two tank system together at the low pressure side...

a complex plumbing project is hard as you must have just all the right fittings; the space constraints are the biggest challenge; i also want to avoid having to modify the existing gas lines by rebending them as they have been work-hardened

i consolidated two regulators into one; there is a lot more than what meet the eyes because the two propane tanks are on each side of the Vanagon, as well as appliances (because of the Carver P4 furnace) that the gas line enter at oppsite sides

as it stands I am unable to finish the propane system plumbing until I can procure a high pressure hose like this in 8-foot length however

No comments:

Post a Comment